“Efficiency."

These are the two letters(효율, in Korean) that best abbreviate the GTI Energy carbon capture facilities.

this reporter looked around facilities with Dr. Akpollat and Mr. Mohammed Hussain, Senior Director of Engineering Operations.

CCS technology received full-fledged attention with Paris Agreement in 2015, but the initial CCS equipment Dr. Akpolat showed me, was similar age with this reporter(30s).

How could this be possible?

The answer was in the 'continuity' mentioned in the other article.

▲Dr. Osman Akpolat of GTI looks up at the initial carbon capture device and explains it to a reporter.(GTI Energy)

“Originally used to remove carbon dioxide (CO2) or H2S (hydrogen sulfide), it is now used for carbon capture," Dr. Akpolat explained of this early CCS equipment.

GTI Energy has “recycled" the equipment already used for gas research as a new technology flow emerges.

(It is a natural law to raise chickens for a longer time to get eggs every day, but it is often not used in the Korean circumstance, which is thirsty for immediate results.)

The early model boasted a huge size like the first computer in the world. (As you can see in the picture, the top is higher than the building.)

Dr. Akpolat also said, “I'm pointing my finger at the sky.", while talking pictures with this equpment,

But The later equipment, small RPB (Rotating Packed Bed), was like the computer became an iPhone.

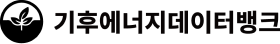

▲RPB devices used in rota cap system.(GTI Energy)

It seems that much smaller and more efficient.

Combining this and advanced solvent tech is ROTA-CAP system that GTI Energy mention first when it comes to carbon capture process.

In this regard, Dr. Akpolat explained, “The rotation allowed gas and liquid to combine better and the reactor size to be smaller."

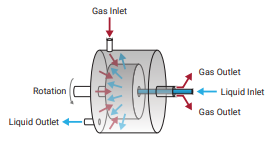

▲Rota cap system, carbon capture device.(GTI Energy)

The rotating system inside the ROTA-CAP allows flue gas (combustion gas generated in the process of burning fuel) and CO2 capture solvents to meet more.

Once injected into the ROTA-CAP system, the flue gas and the collecting solvent circulate and contact each other in opposite flows.

Flue gas filled with CO2 forms a radius flowing from the outside to the inside, and a solvent for collecting CO2 forms a radius flowing from the inside to the outside.

The rotation on this axis generates a centrifugal force greater than gravity, enabling faster and more efficient CO2 capture than before.

▲Basic structure of Rota cap system,.(GTI Energy)

GTI Energy sees the system as a key breakthrough, not only in size problems but also in cost problems.

Compared to the existing system, it has already achieved a 30-50% cost reduction and is known to be suitable for actual carbon capture such as power plants and industries.

In addition to the carbon capture device, Mr. Akpolat also introduced the latest electric reformer, which has never been operated before, only three months have passed since it was manufactured.

Reformer refers to a device that produces fuel by reforming biogas or discarded carbon.

▲Electric Reformer, less than 3 months old, is scheduled to start testing this summer.(GTI Energy)

According to GTI Energy, electric reformers have resolved the contradiction that existing natural gas reformers must generate carbon again to make other fuels with carbon.

Of course, energy efficiency alone cannot keep up with natural gas firepower. but it is smaller, and has a faster speed of turning on and off.

GTI Energy expects the device to be the first step in the E-fuel (Electricity-based Fuel) process, which converts carbon into internal combustion engine fuel such as aviation fuel or automobile fuel.

To this end, a test is scheduled this summer to convert biogas and CO2+H2 gas for 250 hours each.

GTI Energy has set the goal price of aviation fuel to be produced through the device at $2.75 per gallon.

In other words, the project's goal is to lower the price of Sustainable Aviation Fuel (SAF), which currently exceeds $6 per gallon, to the level of general aviation fuel.

On the way out after touring the equipment, we saw the plane taking off from Chicago's O'Hare International Airport near GTI Energy.

In Illinois, where Chicago is located, economic activities with 95.5 billion dollars per year (about 131.2 trillion won) and 500,000 jobs are carried out in relation to the airport.

“the fuel that made here can be over there," Mr. Hussain said, referring to the plane taking off.

In fact, major U.S. airlines such as Delta and Southwest have already planned to replace 10% of all aviation fuel with SAF by 2030.

It was a contrasting moment for this reporter to watch GTI Energy researchers looking up the sky and drawing ways to utilize carbon while Korea is still bowing under the sea to find a place to throw out.